Popular Design for Washing And Drying Line - Eddy Current Separator – Baonan

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Popular Design for Washing And Drying Line - Eddy Current Separator – Baonan Detail:

Eddy Current Separator

Brief introduction

Eddy current separator is mainly used to recycle the non-ferrous metals from industrial and life waste, the typical processing objects are: copper (aluminum) power cable, aluminum products, auto waste, nonferrous metal chips, printed circuit board ash, glass of non-ferrous metals, electronic waste, Poly-metallic mixture , cast copper (aluminum) sand mixture and aluminum dross, etc.

Raw materials for processing:

1.Electronic waste disposal (refrigerator dismantling line).

2.Separation of aluminum cans and ferrous metals.

3.Separate aluminum or copper block from the sections of abandoned cars.

4.Separate non-ferrous metals from the glass scrap.

5.Separate non-ferrous metal impurities in some production lines(such as plastic recycling production line).

6.Separate non-ferrous metals from the wood.

Features

1.Easy to operate and install

2.Low energy consumption

3.Separate ferrous and non-ferrous metal automatically

4.Good sorting effect , and material with small size can be sorted.

5.Concentric rotor has large separation area and strong separation force.

6.A variety of models, a variety of structures for customers to choose

7.Protective device to give warning when it is in a dangerous condition

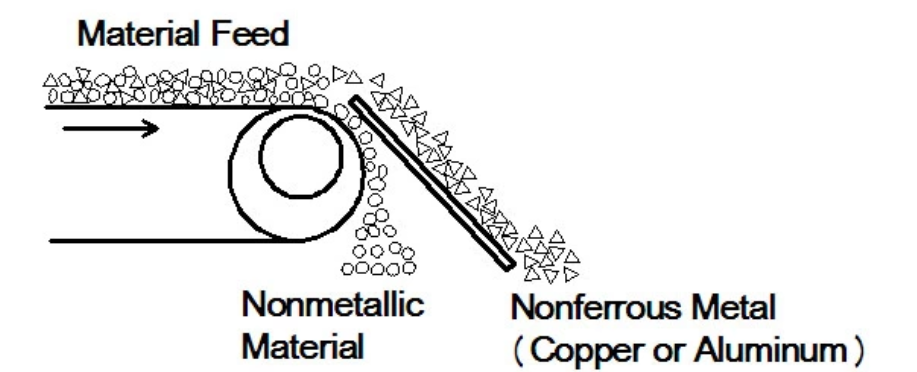

Working Principles

Eddy current separation is based on the use of a magnetic rotor with alternating polarity, spinning rapidly inside a non-metallic drum driven by a conveyor belt. As non-ferrous metals pass over the drum, the alternating magnetic field creates eddy currents in the non-ferrous metal particles repelling the material away from the conveyor. While other materials drop off at the end of the conveyor, the non-ferrous metals are propelled forward over a splitter for separation

Technical Parameters

|

Model |

Width of Belt (mm) |

Power (kw) |

Capacity (m3/h) |

Over all size L*W*H(mm) |

Weight |

|

TE-600 |

600 |

15.49 |

3-5 |

3300*1500*1200 |

1200 |

|

TE-100 |

1000 |

19.95 |

5-8 |

3300*1900*1200 |

1500 |

|

TE-1200 |

1200 |

20.49 |

8-10 |

3300*2100*1200 |

2000 |

Product detail pictures:

Related Product Guide:

While using the "Client-Oriented" organization philosophy, a rigorous top quality command process, highly developed production devices and a potent R&D workforce, we normally provide high quality products, outstanding solutions and aggressive charges for Popular Design for Washing And Drying Line - Eddy Current Separator – Baonan, The product will supply to all over the world, such as: Karachi, Berlin, Turkey, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!