Heavy duty Metal shredder Hammer shredder

Short Description:

Metal shredder designed to shred a wide variety of scrap metals ,aluminum ,car body,motors,scrap bales etc. By smashing and compressing,the shredder will remove impurities,raise density,lower transporting and smelting cost to offer good furnace-charge for smelting plant.

Product Detail

Product Tags

Working principle

Hammer crusher is mainly by impact to crush the material. Material into the hammer mill, suffered shattered by the impact of the high-speed rotary hammer, the crushed material, obtained from hammer broken hammer kinetic energy, from high speed toward the body flap, screen, meanwhile material impact each other, have been broken many times, the clearance of the material is less than the bar, from the eduction in clearance, individual large material, on the bar again by the impact of the hammer head, Grinding, extrusion and crushing, the material is hammer break machine hammer from the gap extrusion. To get the granularity you need.

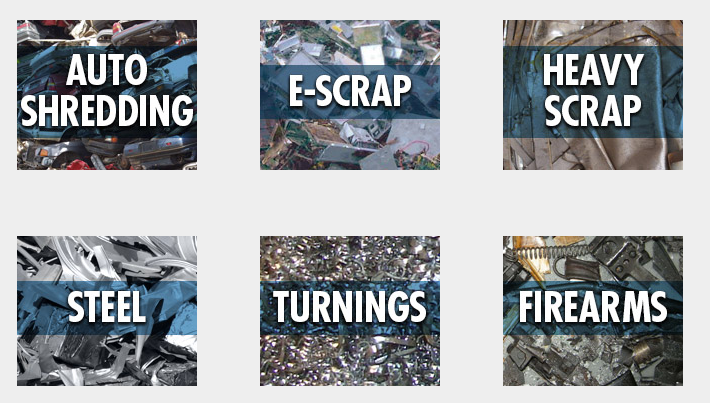

Input Scrap Materials

① Scrap aluminum such as aluminum engine blocks,aluminum car wheels, aluminum profiles/extrusions, aluminum castings etc. Copper motor stators etc.

②Whole or flattened car bodies (without tires, fuel/gas tanks, engines & gear boxes)

③ Tin plate material

④Electrical appliances (without motor, compressor, axles)

⑤Bicycles & similar materials

⑥Empty tanks (without liquid materials & painting, etc)

⑦ Household appliances, white goods scrap.

Other scraps suitable for shredding

Your benefits at a glance

easily replaceable wear parts

segmented screen for faster screen replacement of the worn segments

a counter knife that can be adjusted from outside during operation,

frequency-controlled drives for adapting the rotation speed

Technical specifications

| Technical Data |

HM100 |

HM160 |

HM200 |

HM250 |

| Dimension (L/W/H) (mm) | 5000*4500*5000 | 5000*5000*5000 | 8000*8300*7000 | 8000*10000*7000 |

| Rotation speed (r/min) | 500-800 | 500-800 | 500-800 | 500-800 |

| Number of hammers (PCS) | 18 | 22 | 24 | 30 |

| Weight of hammers(kg/piece) | 25 | 45 | 60 | 75 |

| Chamber inner diameter (mm) | 1000 | 1600 | 2000 | 2500 |

| Motor power (kw) | 180 | 260 | 450 | 600 |

| Hydraulic system Drive power (kw) | 7.5 | 15 | 15 | 30 |

| Throughput (e.g. meatballs) (tph) | 3-5 | 5-10 | 10-15 | 15-25 |